- World renowned Four D Latex sheeting

- Incredible physical properties, consistency and tolerances

- Multiple industry applications

- 850% elongation and high tear strength

- Widths up to 4 Metres

- Thickness from 0.18mm to 3.00mm

- Wide range of colours available

Back to About Sheeting

Natural Latex

Description

Product Description

Four D Rubber has a global reputation for producing the highest quality thin latex sheeting. With over 50 years of experience our unique formulations and processes produce sheet with unsurpassed properties. We use only the highest grades of latex and other ingredients to ensure material of incredible strength and consistency.

The material can be produced in widths of up to 4 metres and thicknesses from 0.18mm to 3.0mm with a tolerance better than 10%. We have the ability to produce material in almost any colour and in different finishes with smooth or textured surfaces to assist with grip or bonding.

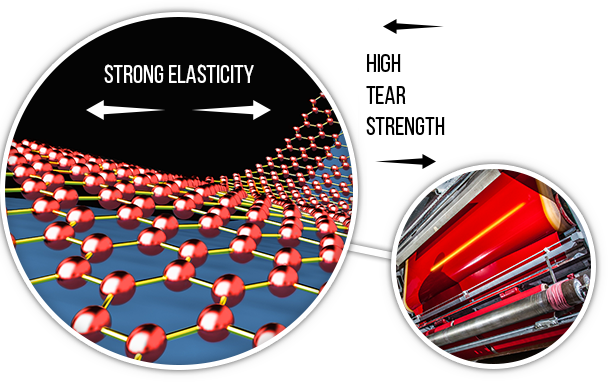

The physical properties of the material retain the characteristics of the latex with incredible elongation, elasticity, tear strength and abrasion resistance.

Technical Details

Our natural rubber sheet is available in widths up to 4 meters and thicknesses from 0.18mm – 3.00mm with a tolerance of +/- 10%. The material has an elongation of 850% and high tear strength.

Sheet is normally supplied with a smooth finish on one side and textured on the other to assist in bonding in grip. Material with a smooth finish on both sides is also available together with high gloss surface. We have a colour range of 60 standard colours but colour matching is available. This material contains natural rubber latex. For sensitive applications, synthetic natural rubber sheeting is available. We can also produce bespoke variations including high temperature and anti-static sheeting.

Our Natural Rubber Latex Sheeting is used across a multitude of industries from fashion and fitness to Industrial and Medical.

Four D Manufacturing

Through years of experience, knowledge and testing, Four D have created a rubber sheeting that has the highest quality. We have our own formulations and proprietary processes to produce the ultimate latex sheet material. With the core of our manufacturing in the UK we maintain incredibly tight control over quality and consistency to meet even the most demanding customer’s requirements.

ISO 9001. 2015 and ISO 13485. 2016 accredited

Featured Products