4D Technology

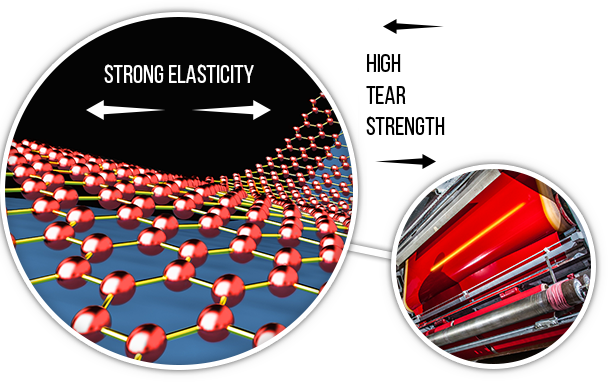

- 800% stretch potential before product starts to deform

- Strong lattice molecular structure ensuring high tensile strength

- High quality surface finish

- Highly malleable allowing precise thickness control

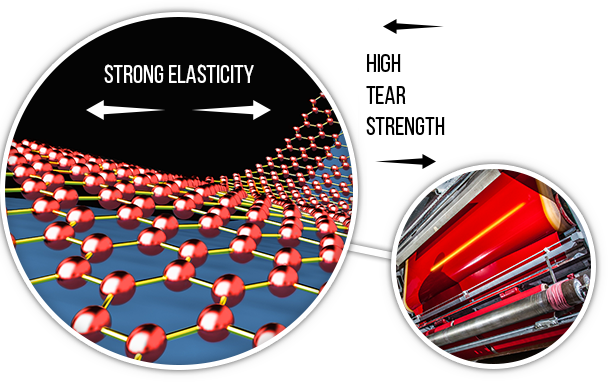

Natural rubber is the outcome of dried natural rubber latex which has been compounded and processed. The chemical structure of natural rubber is very similar to that of natural rubber latex. Specific manufacturing techniques can alter the physical properties of natural rubber to suit certain specifications such as dimensions and tightness.

Natural rubber latex is the white sap that comes from the rubber producing tree, hevea brasiliensis. This forms the basis of all rubber based products although specific refinements and compounding processes transform it into varying physically altered specifications. Natural rubber latex has extreme elongation, tear resilient and durability properties.

Synthetic rubber is the term for artificially moderated rubber which has been mainly synthesised from petroleum by products. Synthetic rubber is commonly known for its elasticity.

The Four D technology badge is a stamp of manufactured excellence as it represents our utilisation of the best natural ingredients, innovative processes and superior quality material characteristics.

At Four D we have complete, in house control over all key steps, from rubber formulation through to manufacture, finishing and presentation. We use unique, proprietary technology at every stage. This ensures that the inherent properties of latex are preserved and enhanced, and all our sheeting and products are made to the highest standards.